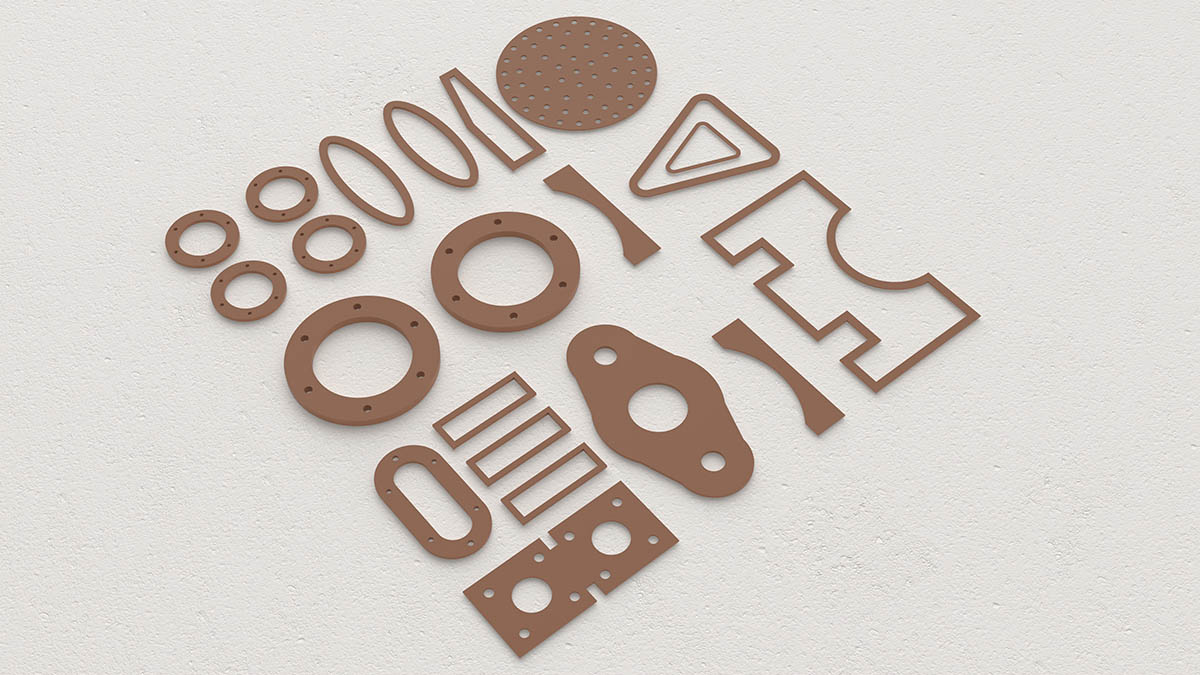

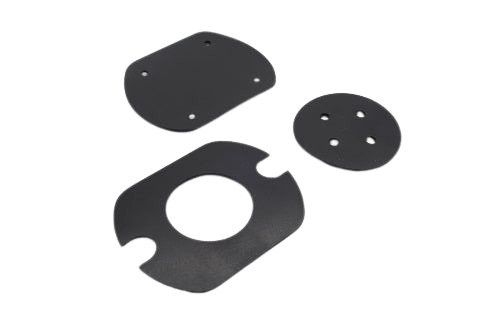

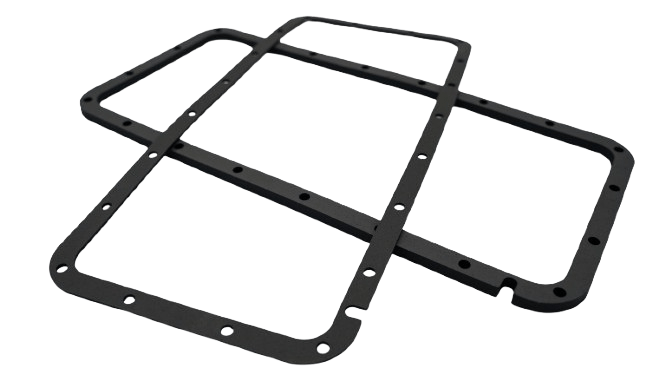

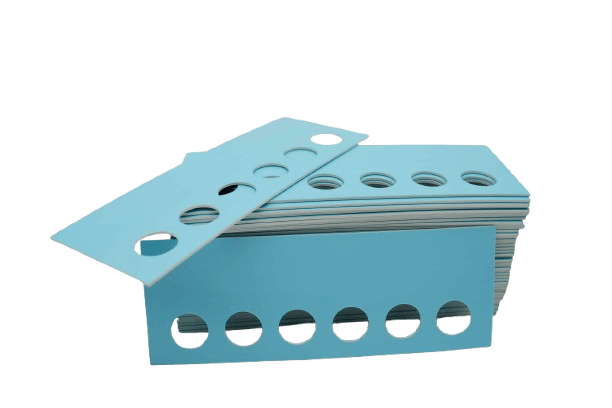

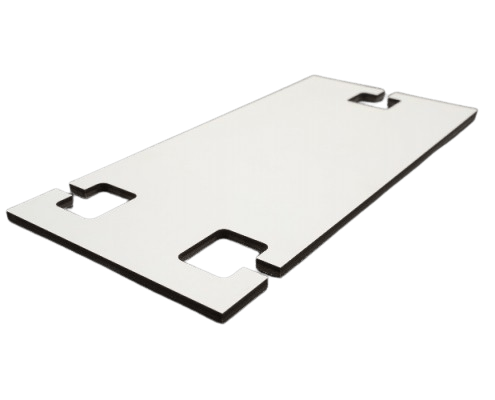

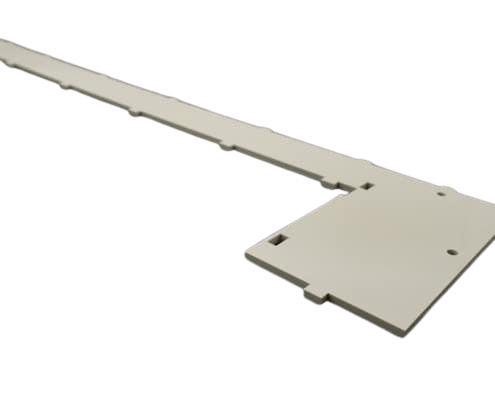

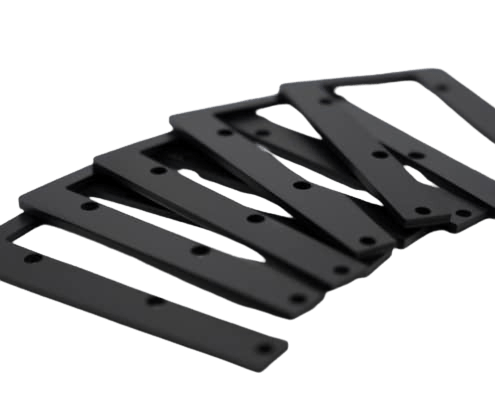

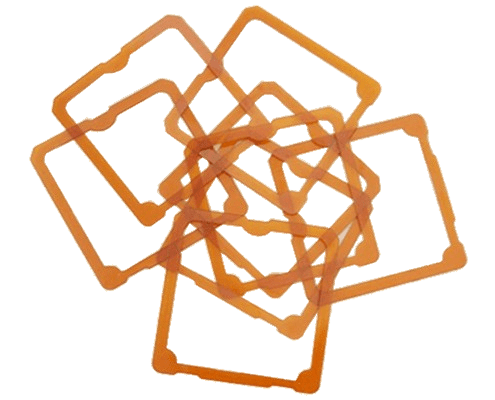

PUR (Polyurethane Rubber)

Rubber

Polyurethane rubber (PUR) is a versatile elastomer that excels in wear resistance, elasticity, and mechanical strength. The material combines the flexibility of rubber with the durability of plastic and is widely used in demanding industrial environments. PUR withstands high dynamic loads, has excellent tear and tensile strength, and offers a wide range of hardnesses from soft to very hard.

Well-known trade names for PUR include Vulkollan®, Adiprene®, Urepan®, and Elastogran®. These grades are used worldwide in industries such as machinery, transport, mining, and printing.

- Laser cutting

- Milling